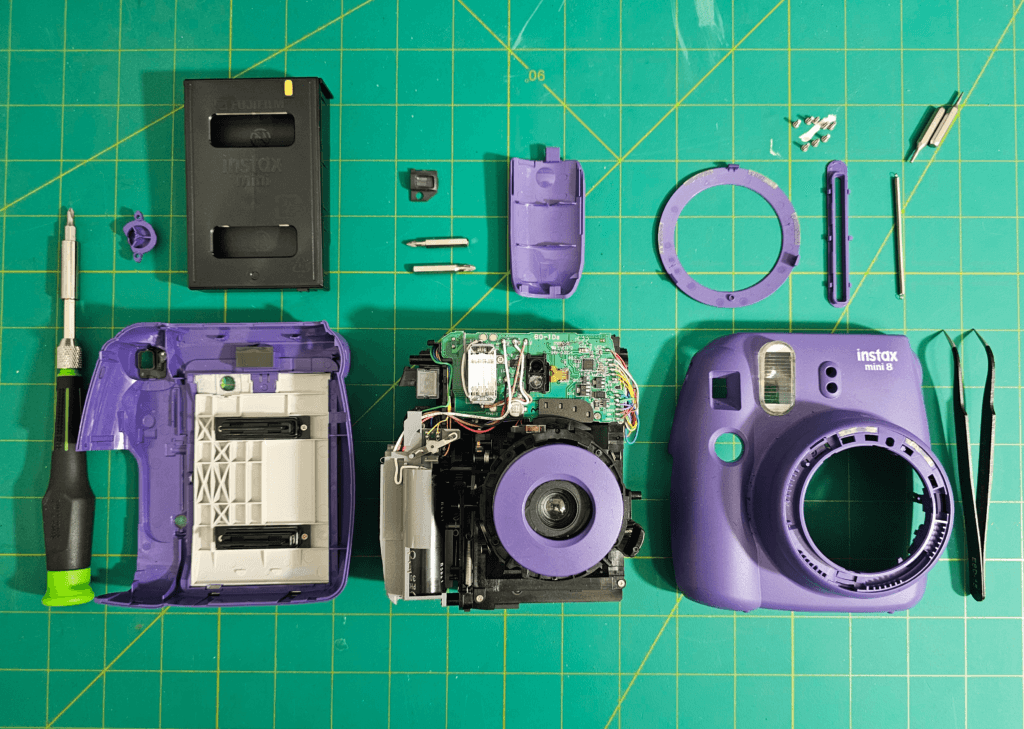

Fujifilm Instax Mini 8 teardown analysis

The following post is part of a teardown series written by Shivam Dehinwal, a product design engineer and member of the informal freelance collective, based in Southern California. From toys to energy storage systems, he’s built a few things. When he’s not building, Shivam takes products apart and unfolds the story behind their development, part by part. All images are courtesy of Shivam Dehinwal.

Fujifilm Instax Mini 8 has a total of 16 springs.

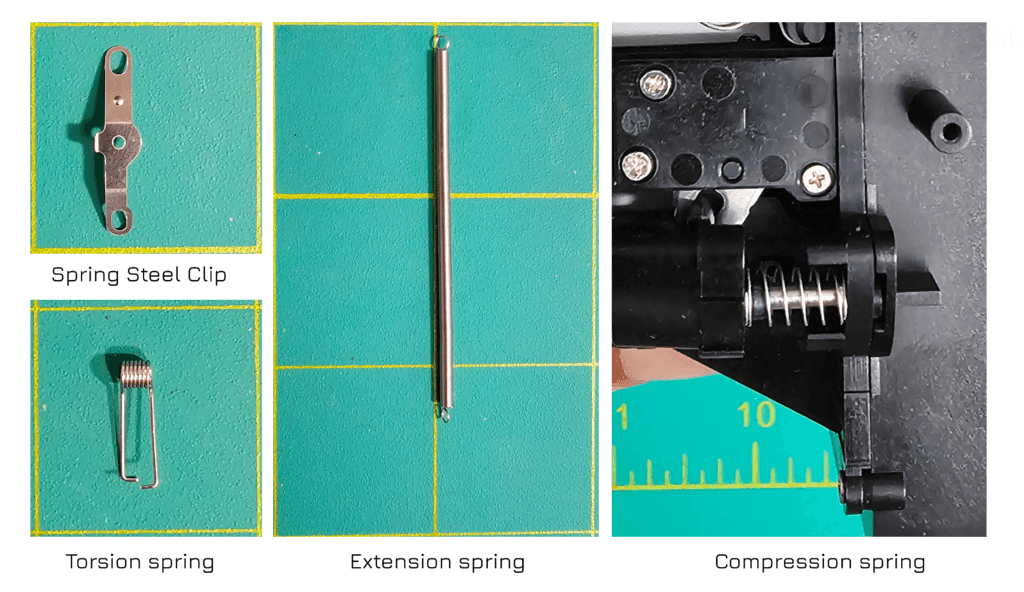

These 16 springs can be divided into 4 categories:

- Spring steel clips

- Torsion springs

- Extension springs

- Compression springs

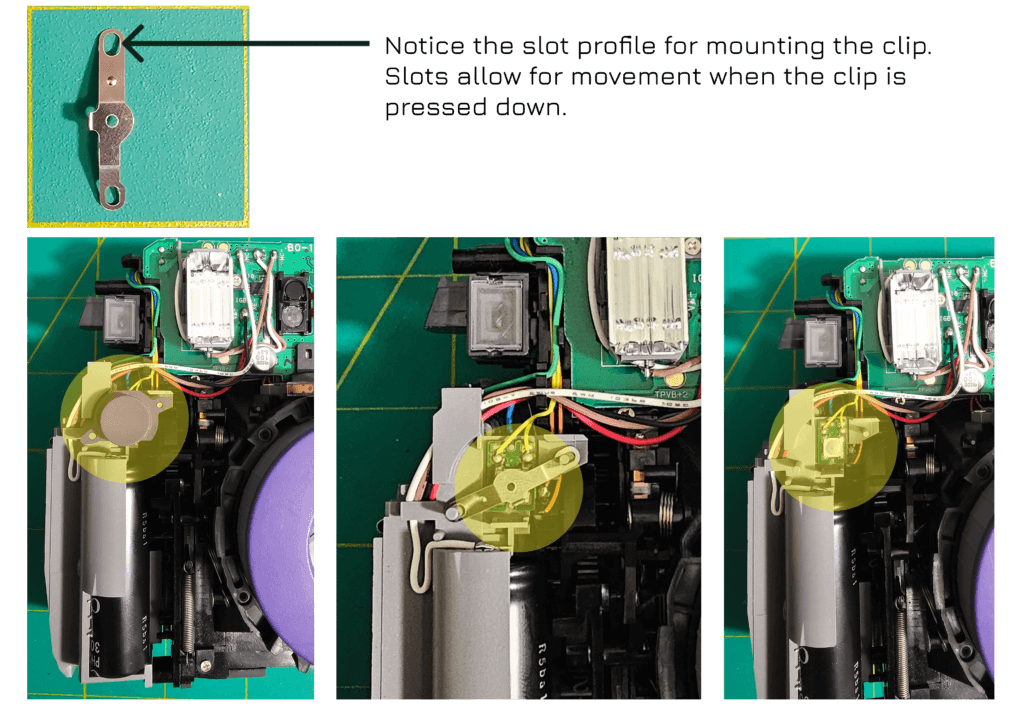

One of the spring steel clips is used on the click button. This clip pushes the button against the frame and eliminates slack and rattle on the button for a nice clicking experience. Under the clip is the tactile button.

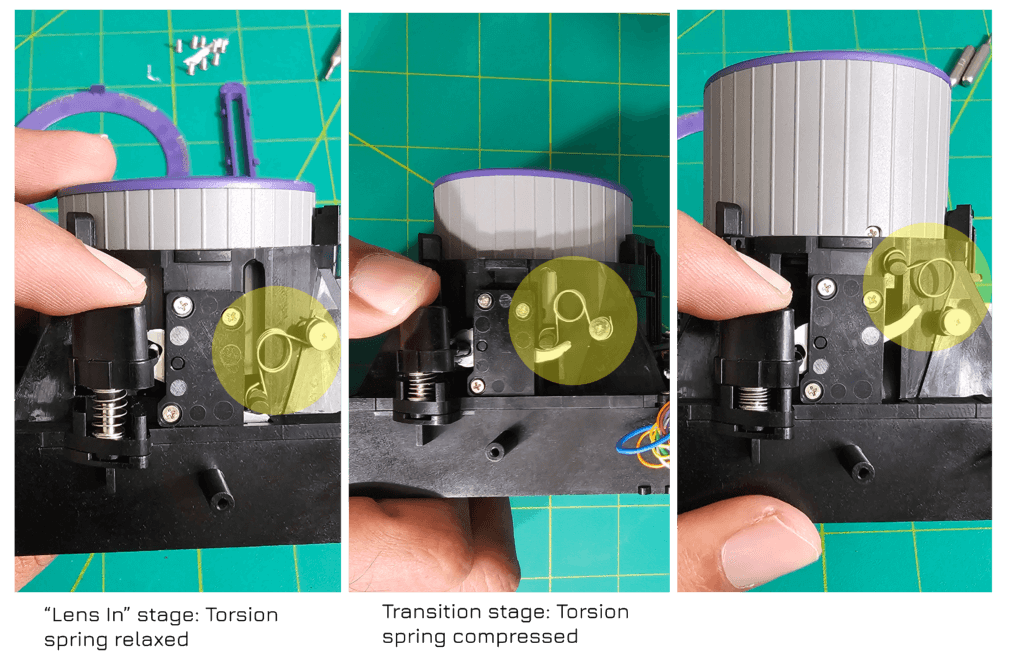

Torsion springs are used to create two stable states for the lens: lens out and lens in. In these two stages, the torsion springs are relaxed, but during the transition, the torsion spring is compressed and pushes the lens in the direction of the applied force.

Watch this video snippet to see the above in action!

There’s an extension spring under the mode-control dial that adds tension to the dial for a nice tactical experience. Notice how the spring is bent 90 degrees and mounted inside the camera on one end. Not sure if that is a common practice but I found it interesting.

Watch this video snippet to see the above in action!

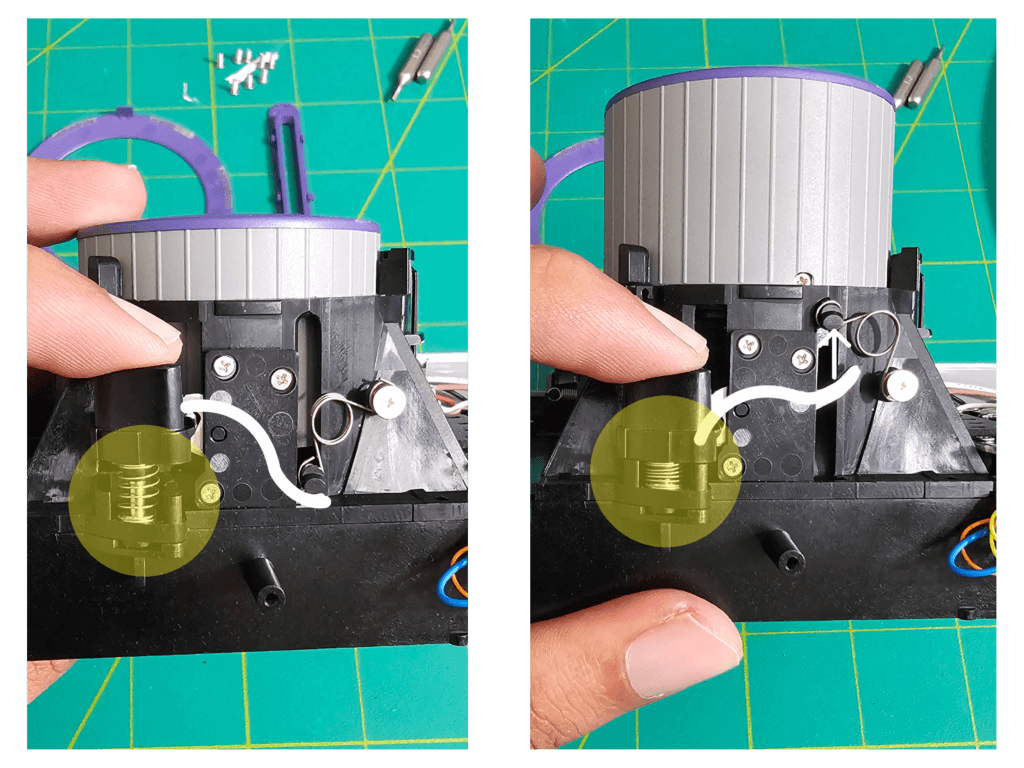

There’s a compression spring under the button used to open the lens. The spring pushes the button up against the frame, eliminates rattle, and provides the bounce back effect. The range of motion for this button is much longer than the picture click button and thus a compression spring is a better choice here. This button is connected to a lever that controls lens position.

These were just four use cases of the different types of springs. The camera makes good use of the springs for other purposes as well, for example:

- A torsion spring pair is used to push the films.

- An extension spring is used on the film-counter dial.

- Torsion springs are used to push the rollers through, which the film passes.

informal is a freelance collective for the most talented independent professionals in hardware and hardtech. Whether you’re looking for a single contractor, a full-time employee, or an entire team of professionals to work on everything from product development to go-to-market, informal has the perfect collection of people for the job.