What can (actually) be made in the USA?

We’ve written before on why China is the manufacturing powerhouse of the world and why it’s hard to manufacture in the USA, but we haven’t spoken about the cases in which it does make sense to make stuff here. To recap: China has created an incredibly inexpensive and efficient option for manufacturing by creating entire towns and cities that are purpose-built for making things. They’ve also boosted these efforts with strong government incentives, very relaxed labor laws, and little care for the environment. From a cost and timelines standpoint, China is still the best option for manufacturing nearly all products.

Tariffs and the USA

Recently, we’ve heard a lot about how tariffs are supposed to spur American manufacturing and allow us to finally regain our title as a manufacturing superpower in the world. I have many strong feelings about why this won’t happen, but I’ll save you a rant with a quick summary for now:

- We lack the infrastructure to ship manufactured goods inexpensively and quickly.

- We have manufacturers spread too far away from each other to make it easy to collaborate, communicate, and ensure high-quality products are made.

- We’re lacking a workforce that is trained in manufacturing and willing to work the repetitive and boring jobs that are inevitable with manufacturing.

- Our culture is more self-protecting and less collaborative than China.

- We (currently) have laws in place to protect worker and environmental safety and minimum working wages that make it too expensive for customers to want to buy most products made in the USA.

These issues compile into the sad truth that even when comparing between manufacturing in the US and manufacturing in China with steep tariffs applied, the costs still typically come out in favor against making things here.

So, what can we make here?

There are always exceptions, and we should look at some use cases where US-based manufacturing may be competitive. We’re mainly competitive on products that are either simple to make and assemble, can be highly automated to reduce labor costs, are too large to ship here, or where security and IP are a primary concern. Let’s look at some examples of each.

Things that are simple to make and assemble

One type of product where you typically see a “Made in the USA” stamp are items which can be easily manufactured and assembled. These span the gamut from ironing boards and disposable pie tins to brooms and mops. While they aren’t fancy items like a cellphone, they’re commodities and home goods with a larger customer base.

Clearly “Made in the USA” is the strong selling point here. (Image: Seymour Home Products, Handi-Foil, USA Broom)

My favorite example is GreenToys — a company creating beautiful and robust children’s toys from recycled plastics. I love the mission, the design, and the quality of these toys, so they’re already a winner in my book. However, the mechanical engineer in me also noticed that these toys are all snapped together and feature really clever fastening methods. By eliminating the need for screws, this company can save on materials and assembly time – reducing the costs to manufacture. They can also charge a premium compared to other toys due to the “green” branding and marketing strategy, as their target demographic is willing to pay more for products that are more environmentally friendly.

These toys rock! (Image: Green Toys)

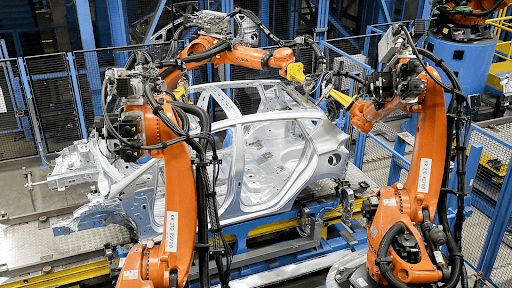

Things that can be assembled with lots of automation

Car companies are often pointed to as great examples of how we can manufacture things in the US. Their secret? They use robots — lots and lots of robots. This reduces the need for skilled workers, ensures high-quality assembly work, and allows for dangerous dirty and dull work to happen stateside. A typical automotive plant utilizes custom robotics for loading and unloading stamping tools, welding the car body, painting the vehicle, moving subassemblies, and assisting with positioning-cumbersome items like seats during assembly. There are still many humans involved on most car assembly lines, but they’re used only when necessary for jobs that require increased dexterity like running cables and fuel lines or when automation becomes too complicated.

Automated assembly of a Ford vehicle. (Image: WIRED)

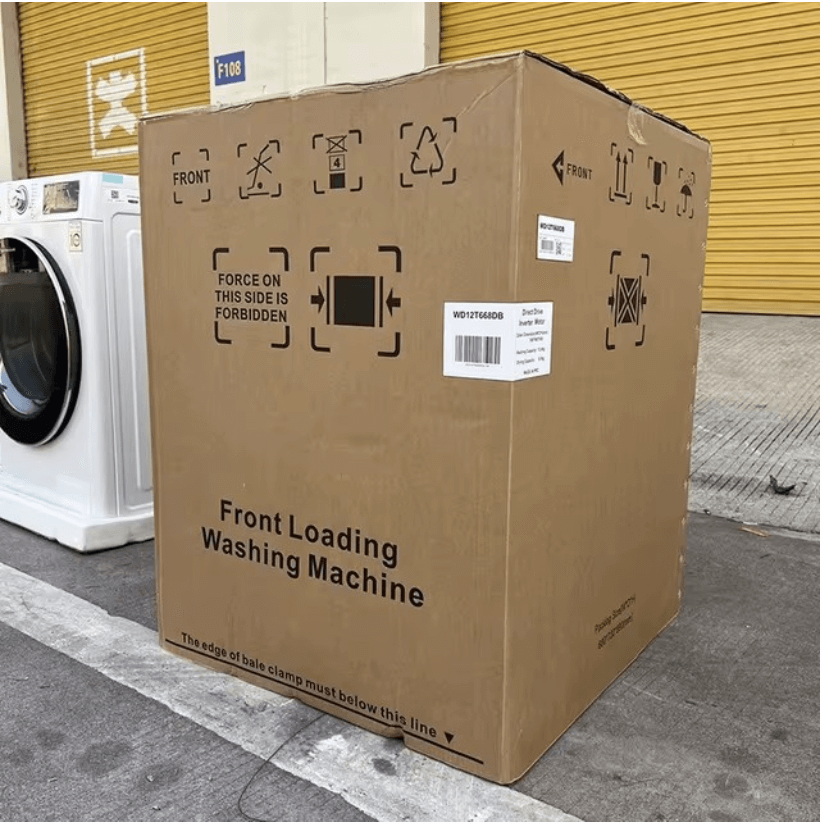

Things that are expensive to ship to the United States

Large or fragile appliances tend to be assembled in the United States because they’re too unwieldy, fragile, or expensive to ship to the US. Whirlpool, GE, and Frigidaire have domestic assembly lines for ovens and ranges, given that shipping a full-size range can be costly and damage-prone. Whirlpool assembles a few refrigerators, ovens and washers in the United States as well. These products are heavy and bulky and need to be cost competitive with other brands, so reducing shipping costs is a high priority.

This looks like it sucks to ship. (Image: freight sidekick)

Things that are “sensitive”

I’d bet the majority of items made in the United States are made here simply because they have to be. These include items with trade secrets, such as military aircraft components or telecommunications equipment. The risk of trade secrets falling into the hands of the wrong individuals are too high to justify the reduced costs of manufacturing elsewhere. With the exception of consumable items like ammunition, the quantities of these products tend to be lower as well — so the costs per item are already more expensive to produce.

Verizon telecom antennae. (Image: NBC)

Other items I’ve seen made domestically include textiles like bags and some high-end clothing, footwear, and furniture. The companies that make these items typically use the Made in the USA branding to attract a specific audience willing to pay more for “quality” goods made here.

Is it actually “Made in the USA”?

It’s also worth noting that while the examples above may be assembled in the US, the materials and components required are typically sourced from other countries still. Aluminum and steel used in automobile manufacturing may be sourced from China or Canada, for example. The tools used for injection-molding plastic parts are also typically machined in China and shipped to the US for use. Most electronics components — like resistors, capacitors, inductors and many microcontrollers — come from Southeast Asia. So the reality is that very few items are purely “Made in the USA” and are actually “Assembled in the USA with foreign components,” but that sounds far less sexy. The reality is that products are complicated and made from components sourced from all around the world due to various countries’ expertise, resources, capabilities, and policies. Some automotive components cross between Canada and the US eight times before final assembly. Throwing tariffs on these components would immediately increase the costs to manufacture, which would directly impact the customer.

Want to learn more? I highly recommend watching the documentary American Factory about a Chinese company manufacturing glass in the US. It highlights the cultural differences between China and American manufacturing incredibly well.